KD - 660S

▶ Mixing Ratio Adjust with special Motor (Power Mixing)�

▶ Quick Mixing Exhaust High Viscosity to Low Viscosity

▶ Durability Strength “Gasket Seal Longevity�

▶ Continuance execution Pre-heating & Bubble Eliminate

▶ Maximum Productivity due to Continuance execution

Dispensing(Robot Continuance Execution )

▶ Fully Secure Stir & Bubble Eliminate Time�

▶ Static Mixer

▶ Interface with Auto Line

Specification

| Mixing Method |

Power Mixing |

| Pump |

Gear Pump |

| Tank |

Resin 60ℓ / Hardener 60ℓ |

| Out Dimension

|

800(W)×1100(D)×1600(H) |

| Power Source |

¢3, 220V , 50~60㎐ |

| Weight |

150㎏ |

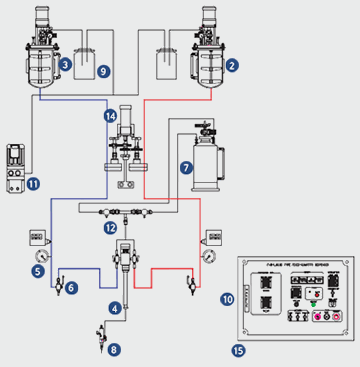

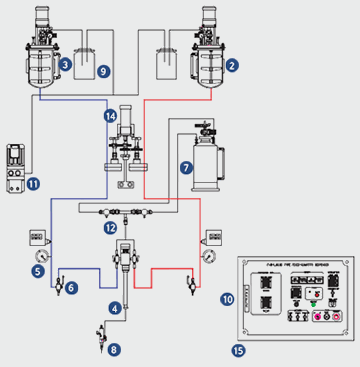

◎Two Liquid Dispener

01 Body Casing

02 Resin Tank [ Resin ]

03 Hardener Tank [ Hardener ]

04 Mixing ass’y unit

05 Pressure Gauge [ Resin, Hardener ]

06 Ratio Valve [ Resin, Hardener ]

07 Clean liquid Tank

08 Dispensing Valve [ Fixing Volume Valve ]

09 Seperator [ Resin, Hardener ]

10 Controller

11 Vacuum Pump [ Vacuum Pump ]

12 Cleaning Unit

13 Pressure over load switch

14 Driver Motor

[ Resin, Hardener, Pump Unit ]

15 Body

▶ Gear Pump Feeding without Additional Drum

▶ Easy changeable Drum

▶ Maximum Productivity due to Continuance execution Dispensing

▶ Designed Low Weight.

▶ Whole parts control easily

▶ Static Mixer

▶ No Restrain of space, Consecutive working

with Auto M/C

| Liquid Pastel |

2K Epoxy, Silicon, Urethane |

| Viscosity |

1~20 cps ( 25℃ ) |

| Mixing Ratio |

100 : 10 ~ 100 : 1000

( Mixing Ratio Adjustable ) |

| Exhaust Volume |

0.22cc / min ~ : |

| Accuracy |

±1% (max) |

| Tank |

sus 304 5ℓ ~ 200ℓ |

| Power |

220V 1Ph - 380 – 3Ph 60㎐ (5kg/㎠)

|

◎Specification

| Division |

KD - 302U |

KD - 660S |

| Liquid Pastel |

Epoxy , Urethane , Silicone |

Epoxy , Urethane , Silicone |

| Viscosity |

1~3000cps ( 25℃ ) |

1~3000cps ( 25℃ ) |

| Mixing Ratio |

100 : 10 ~ 100 : 100 |

100 : 5 ~ 100 : 100 |

| Exhaust Volume |

0.2cc / min ~ |

0.2cc / min ~ |

| Accuracy |

± 1% (max) |

± 1% (max) |

| Tank |

SUS 304 20ℓ× 2 |

SUS 304 60ℓ× 2 |

| Power |

¢3 , 220V , 50~60㎐ |

¢3 , 220V , 50~60㎐ |

◎Specification

| Divison |

KD - 202E |

KD - 640E |

| Liquid Pastel |

Epoxy , Urethane , Silicone |

Epoxy , Urethane , Silicone |

| Viscosity |

1~100,000cps ( 25℃ ) |

1~100,000cps ( 25℃ ) |

| Mixing Ratio |

100 : 10 ~ 100 : 100 |

100 : 10 ~ 100 : 100 |

| Exhaust Volume |

0.05cc / min ~ |

0.1cc / min ~ |

| Accuracy |

± 1% |

± 0.2% |

| Tank |

SUS 304 20ℓ× 2 |

SUS 304 , 10ℓ× 1 |

| Power |

¢2 , 220V , 50~60㎐ |

¢2 , 220V , 50~60㎐ |