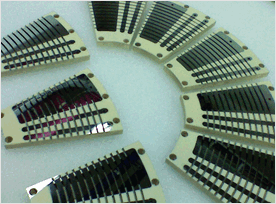

Ceramic Hot Plate Adhesive System

*Three Point Manual Rotate Dispensing

*Vacuum Ceramic Compressed

*Load-Cell Pressure Adjust

*Precision Micro Motor Three Point Compressed�

*Adhesive Height within 3Micro�

*Convenience of working

| SPEC |

| Cartridge Volume |

340cc |

| Size |

1200(W) X 650(L) X 1685(H) |

| Motor |

Precision micro-step motor |

| Load-Cel |

5kg |

| Valve |

Hot Melt |

| Power Source |

220V / 1φ / 50~60Hz |

| Weight |

130kg |

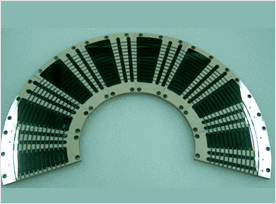

Ceramic Hot Plate Adhesive System(Application)

Ceramic Processing Bonding working

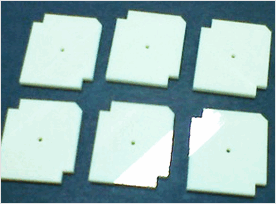

Low Pressure injection molding meting the resin in the Tank.

Protection and moldable the fragile electronic components

by injecting a predetermined amount of the injection mold through a nozzle

*Time Saving Loading/

Unloading continuous production.

* PLC, Touch Screen can control

with easy function

* Exhaust Volume Control each Model`s Data

* Horizontal, Vertical adjustable

*Various Material adjust high adhesive

*Utmost Machine Feature

*Lower Molding with Low Viscosity

*Eco-Friendly Line combination.

*To the safety of workers, apply

palm button, light curtain

| SPEC |

| Machine SIZE |

800(w) x 800(L) x 1850(H)

|

| Molde Size |

180 X 180

|

| Temp |

40 ~ 240℃

|

| Temp. Control |

±1℃

|

| Electric Cap |

4KW |

| Input Voltage

|

AC 220V / 3

|

| Weight |

180kg |

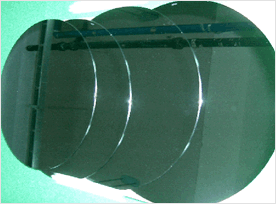

Hot Melt Molding System (Application)

Cell Phone., HF Connector, Car, Electric,

Medicine & Water proof connector, LED,

Micro S/W.

Visual Display of LCD, more accurate Temp, Control

| SPEC |

| Model

|

TR80 LCD

|

| Temp. Display

|

Digital Base

|

| Working Pressure |

0.5 ~ 6Bar

|

| Working Temp |

50 ~ 210℃

|

| IP Level

|

IP30 |

| Consumption Power

|

650Watt

|

| Input Voltage

|

230V / 50Hz

|

| Power Cord

|

4m / Base

|

| Weight

|

1,400g

|

| Accessories

|

| Foot S/W

|

| Cartridge Heat |

| Balancer |

| Blank Cartridge (Including Piston ) |

| Cartridge Adapter

|

| M10_Nozzle

|